Industrial Cutting Tool Sharpening & Repair Services

A lot goes into the sharpening and repair services provided by Southern Carbide. There are as many different types of cutting tools as there are products to cut. However, while the process of each different type is basically the same, each type of tool requires a different machine to service it properly. At Southern Carbide we have the equipment, people and knowledge to service a variety of cutting tools.

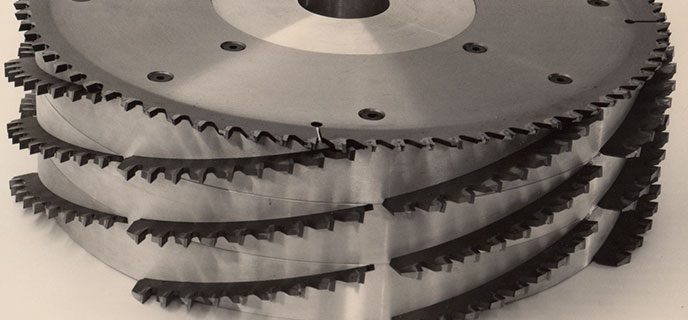

Sawblades

We sharpen saw blades from 2” to 52” diameter, with tooth designs ranging from: ATB – alternate top bevel, TCG – triple chip design, and a variety of combination designs. If blades are bent, we have experienced/skilled personnel that are capable of flattening and tensioning saw blades. We use CNC machines to ensure the highest quality of repair.

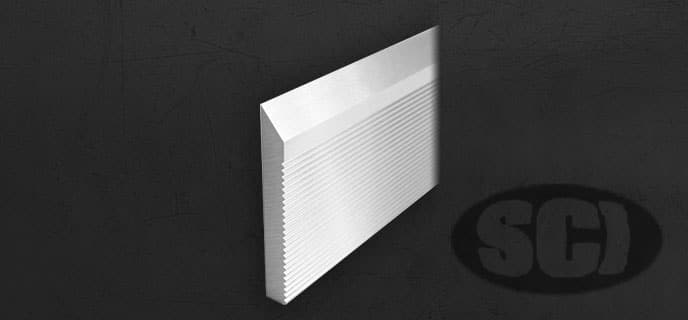

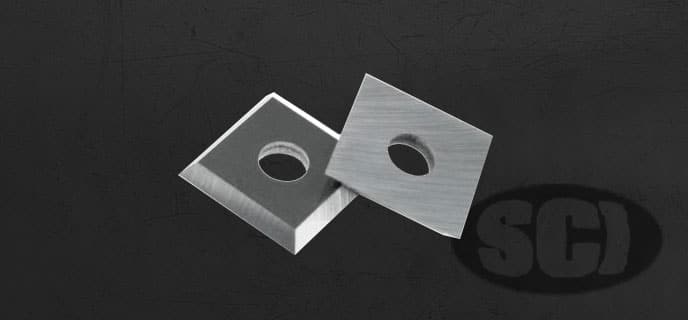

Cutters/Molder Knives

Cutters come in all shapes, sizes and styles. From simple flat groovers to complex multi-piece sets. The most common type is shaper cutters used by cabinet makers and more industrial types like the ones used to make plywood. (T&G, T1-11, ShipLap, RB&B, etc)

- Carbide tipped to high speed steel to solid carbide insert tools.

- We can make any of these for you from a CAD drawing, wood sample or existing tool.

- We sharpen Planer and chipper knives up to 36”.

Hogging Units

We service all brands of hogging units, including Segmented hoggers and solid body hoggers. We offer full service, from assembly to disassembly, sharpening, tip replacement and balancing. We also provide hydraulic sleeves for mounting of heads.

Router Bits/End Mills

These type of tools also come in all shapes, sizes and styles. We provide sharpening of High Speed Steel (HSS), Carbide Tipped (CT) and Solid Carbide (SC) tools.

Ready to get started or need help?

We feel that by focusing on sharpening, repair first we can better serve our customers, providing longer tool life and longer run times.

View Our Products

We have sharpened and re-tipped many different cutting tools, including Hoggers, Cutter Heads, Groovers and various Tongue & Groove patterns. Our service is not simply a one and done operation, rather an ongoing process.