Custom Cutting Tools & Services for Your Application

At Southern Carbide, we have a long history of providing sales, service, and custom cutting tooling solutions to various industries in Louisiana, East Texas, South Eastern Oklahoma, and Southern Arkansas. These industries include the board mill industry, such as, manufacturers of plywood, particle board, oriented strand board (OSB) and medium density fiberboard (MDF). We also offer our solutions to mill-work shops, cabinet makers, and metal fabrication plants.

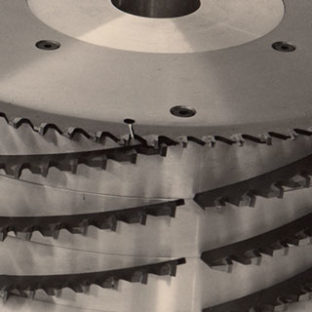

Southern Carbide's combination of sales, service, and custom tooling helps optimize your cutting tool operation for creating plywood and panel boards.

Southern Carbide's combination of sales, service, and custom tooling helps optimize your cutting tool operation for creating plywood and panel boards.

Learn More »

Southern Carbide works with saw mills in Louisiana, Texas, Arkansas, and Oklahoma on improving processes for lumber and industrial cutting equipment.

Southern Carbide works with saw mills in Louisiana, Texas, Arkansas, and Oklahoma on improving processes for lumber and industrial cutting equipment.

Learn More »

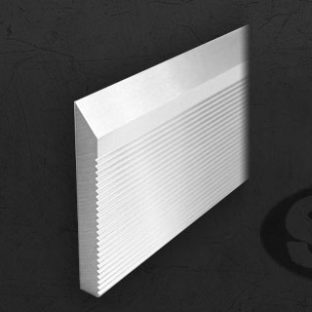

At Southern Carbide, we can assist you in getting the right industrial knives and cutting tools for mill working and cabinetry, including custom templates and patterns.

At Southern Carbide, we can assist you in getting the right industrial knives and cutting tools for mill working and cabinetry, including custom templates and patterns.

Learn More »

Support your crafted furniture operation with cutting tools support, including sales and industrial tool repair service by Southern Carbide.

Support your crafted furniture operation with cutting tools support, including sales and industrial tool repair service by Southern Carbide.

Learn More »

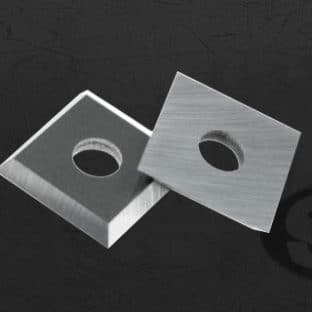

Our cutting tools are prominent in the aluminum fabrication industry for a variety of applications - computer parts, packaging, home appliances, etc.

Our cutting tools are prominent in the aluminum fabrication industry for a variety of applications - computer parts, packaging, home appliances, etc.

Learn More »

Southern Carbide’s machine tools and cutting tools are practical and advantageous to an efficient machine shop facility.

Southern Carbide’s machine tools and cutting tools are practical and advantageous to an efficient machine shop facility.

Learn More »

Ready to get started or need help?

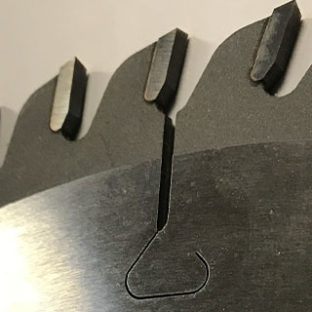

We feel that by focusing on sharpening, repair first we can better serve our customers, providing longer tool life and longer run times.

Browse Our Products

We’ve re-tipped and sharpened all sorts of cutting tools, including hoggers, cutter head bits, and tongue and groove sets. We realize that with so many of these cutting jobs, it is not simply a one and done operation, rather an ongoing process.